To ensure the quality of all our products, we have established and deployed high quality control and assurance standards in addition to well-structured inspection procedures at each critical step of our production process. They are in place throughout the production process to identify and prevent potential defects in the products.

Our quality control procedures primarily consist of the following:

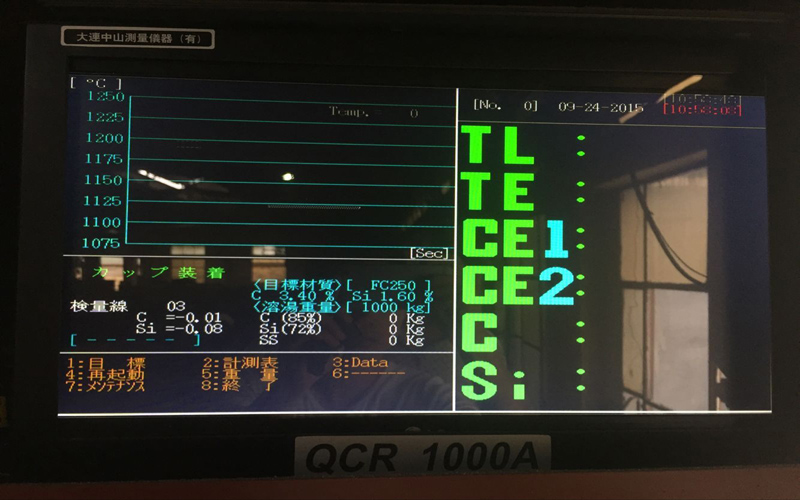

1.Control the melted iron quality by furnace front analyzer.

2.Chemical composition is tested on each individual ladle using a spectrometer.

3. Metallographic microstructure is analyzed by microscope on-side during metal pouring. it’s conducted twice for each ladle-from the beginning of pouring to the last iron liquid pouring.

4. Testing bars which are used for testing the tensile strength(elongation rate)are made in each ladle and can be kept for at least two years.

5.Hardness tester,test the hardness of the material.

6.Paint film thickness gauge, test the thickness of casting product.

7.Precision detection of dimensions, shapes, and positional tolerances of workpieces using three coordinates using Coordinate Measuring Machine (CMM).

Cassie

Cassie

Sales Manager

Sales Manager