Weiben Machinery

Green Sand Casting is used to produce a wide variety of metal components with complex geometries. It requires sand, clay and water to be mixed together to form a mould material that can be compacted around a pattern to produce a mould. Water develops the bonding characteristics of the clay, which binds the sand together . These parts can vary greatly in size and weight, ranging from a couple ounces to several tons.

It is adaptable to a very wide range of alloys and production quantities. Hollow shapes can be produced in these castings through the use of cores. Sand-mold casting is by far the most common casting process used in industry.

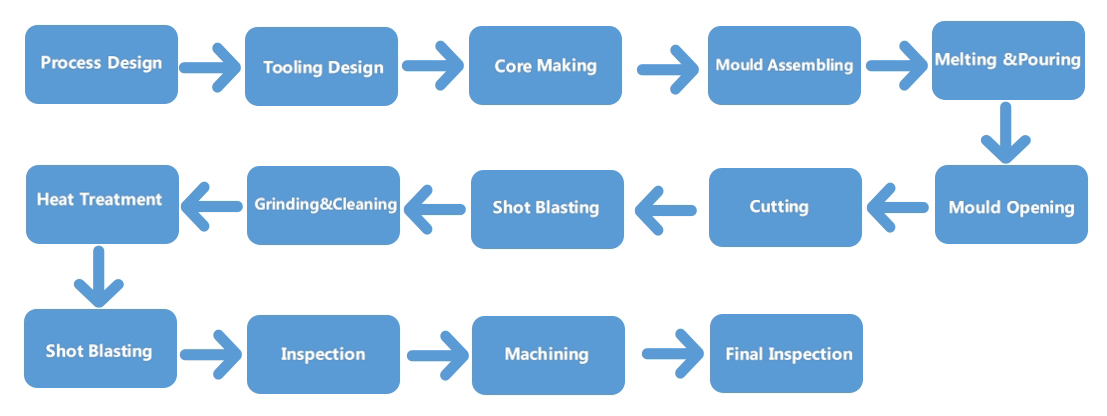

The Process of Green Sand Casting

Copy©2013 | Weiben Machinery . | Sitemap

Cassie

Cassie

Sales Manager

Sales Manager